FALUN.

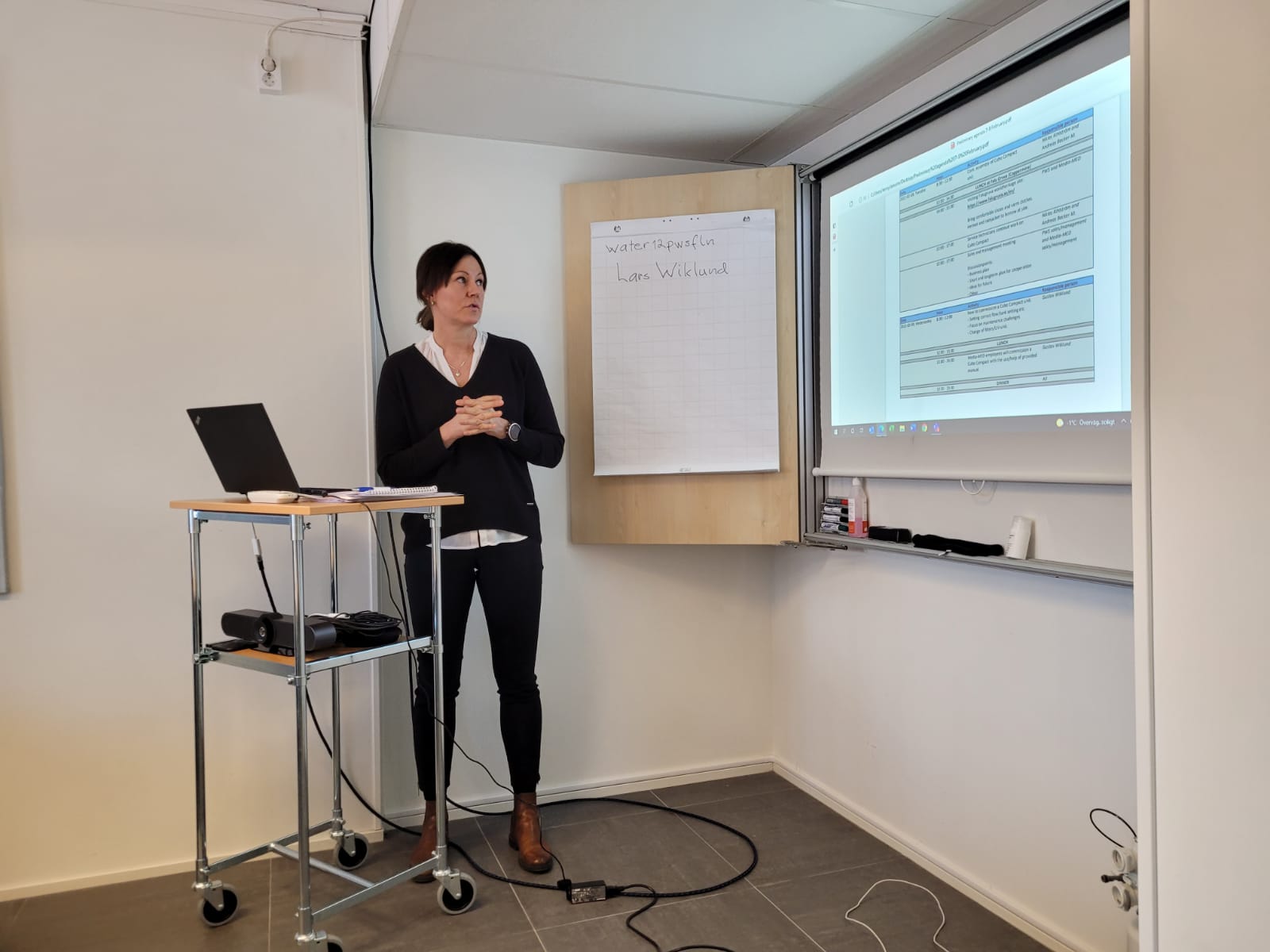

A year ago, Jenny Jansson took the step from COO, Chief Operating Officer, to CEO of PWS, which is now in a new phase in the company's 20-year history.

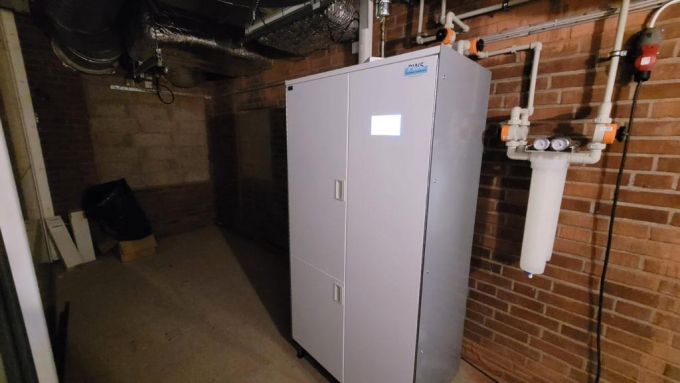

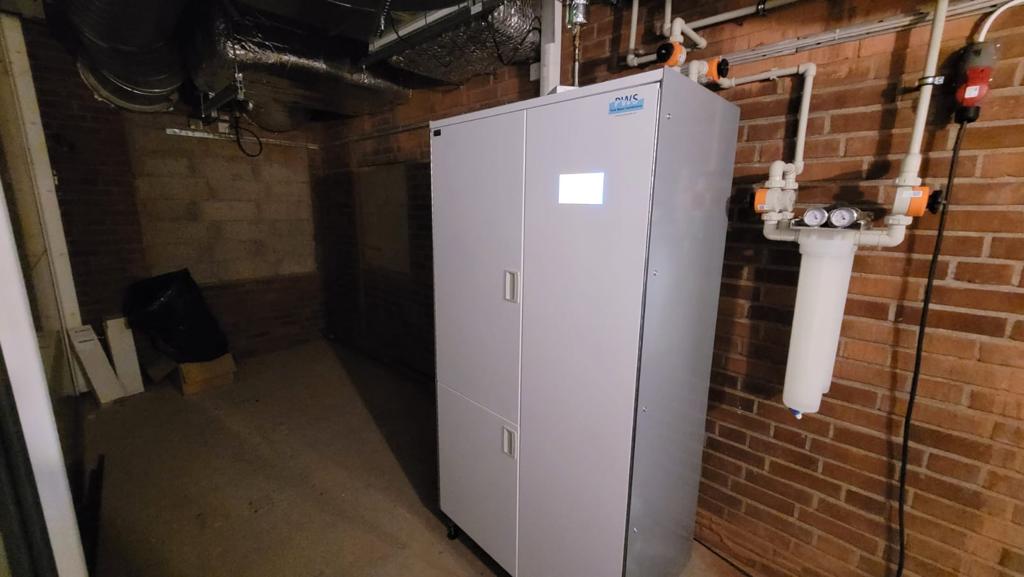

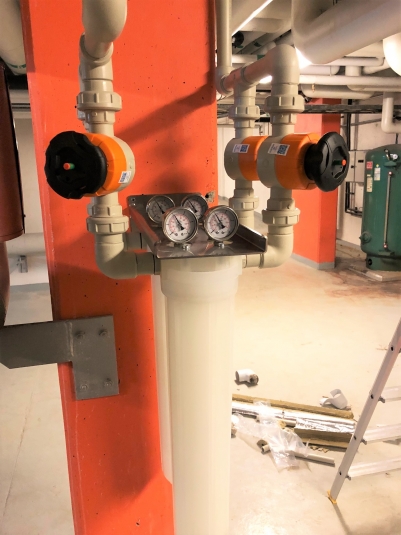

- My mission is to lead the company in a strong expansion with the right margins. We are now working to build a strong network of dealers in Europe, mainly to sell our unique water treatment plant CUBO Compact, says Jenny Jansson.

What did you do before you came to Pure Water Scandinavia?

- I worked for almost ten years at two government agencies before I returned to the private sector as finance manager for Dalelven Produktutveckling AB. In 2016 I started as finance manager at PWS and in 2018 I became COO. I wanted to come to an expansive company where I got a free role to develop in. PWS I had come across during the time at Daleleven.

What was it like going from COO to CEO?

- A big advantage of coming from my previous role to the CEO position is of course that I know the company's operations in detail right from the start. I know what the cash flow looks like. I know our production times, deliveries, orders, products, and employees.

Was there anything that surprised you in the change?

- The range, you are responsible for everything that happens in the company. As an employee, you have your area, or your areas. It can be finance, assembly, administration, logistics, sales or whatever it is. As CEO, I am responsible for all this being done in the best possible way. Still, I cannot and should not dig into details. It takes a while until you find your own way to balance it. Here is a great resource in the CEO network within the Sdiptech group. There we help each other with concrete solutions to concrete challenges.

How do you want to be as a leader?

- I want us all to be transparent with what we do and think. Then we can act quickly and solve problems that arise. I have thought about how I perceived the leaders I met myself and want my leadership to be characterized by dialogue, openness, and clarity. Self-leadership is very important here. If we succeed with that, we can go home satisfied and happy every day after having succeeded with a delivery, won a big deal, or solved a problem together.

Personal qualities that are noticeable in your work?

- Structure. Order. Control. I've always liked that. And I want to create that for the whole company, in all our processes. If I am now going to talk about myself and what I can do, I think I have an ability to see what is missing, to see what it takes for something to work even better. I also get clear ideas about what the next step should lead to and how it should be taken. Now, as CEO, I have the mandate to implement them as well.

How has PWS been affected by the pandemic?

- In 2021, the business itself has been affected very little. We have continued to grow, recruited three new people, and taken home several large orders. What is disturbing is the lack of material in the pandemic's tracks. We have therefore built warehouses in a way we have never needed before so that we can continue to build our advanced water treatment plants.

PWS strength and challenges?

- We work based on a three-year plan and if we start with a strength, that is the position in the Swedish market for water purification. We have very good sales and the machines we have out there also need new filters regularly. One challenge is to expand the network of direct resellers in Europe. Another challenge is to work with preventive maintenance, support, and improvements at the significant number of facilities that are already on the market today. It is also important to keep up with developments and have updated products that meet market needs.

What explains PWS 'strong market position?

- Our smart and cost-effective water treatment plants, not least our CUBO. It takes up minimal space and can be put into production very quickly and deliver pure water to laboratories and hospitals. It was put to the test when the pandemic was at its worst and a hospital in southern Sweden quickly needed a new pure water facility to continue the work in its lab, including covid testing. I should also mention that we have CUBOs in South America, the USA, Singapore, and Australia. Our technology works all over the world.

What do you do to relax?

- When I lead spinning sessions, I am really in a different zone. It is completely unpaid but gives a lot back. Not least thanks to the positive participants. In addition, I get a good workout for myself, and I like to work out, so it is really a rewarding hour.

Jenny Jansson, CEO Pure Water Scandinavia

Education: Master of Business Administration with a focus on industrial economics and organization, Dalarna University

Resident: Apartment in central Falun

Family: Two sons, 11 and 13 years old.

Hobbies: The boys' sports take a lot of time; it is floorball and bandy that apply. I cycle, play golf, ski, lead spinning classes and like to eat at a classic brasserie when there is time for it.

Hidden talent: I'm a hobby hairdresser.

Favourite tech gadget: I do not know if you can call it gadget, but I appreciate my car, a plug-in hybrid, very much.

Håkan Edvardsson

Reporter.se